Linear Stage Motorized

Posted By admin On 12/04/22- 545 results for motorized linear stage. Save this search. 7 S 0 P O N S O A R P A 7 E E D-1-1 U J-1 0 F J-1-1. Under $230.00 - apply Price filter. $230.00 to $1,040.00 - apply Price filter. Over $1,040.00 - apply Price filter. S p K o L P Y S N n C s o W O r 9 e d. Ball Screw Linear CNC Slide Stroke 1001000mm Long Stage.

- Meticulously-engineered pneumatic, hydraulic, manual and motorized linear stages for ultra-smooth movement and hyper-accurate positioning. Gilman’s precision linear stages — also referred to as translation stages.

The Advantages of Using a Linear Motor

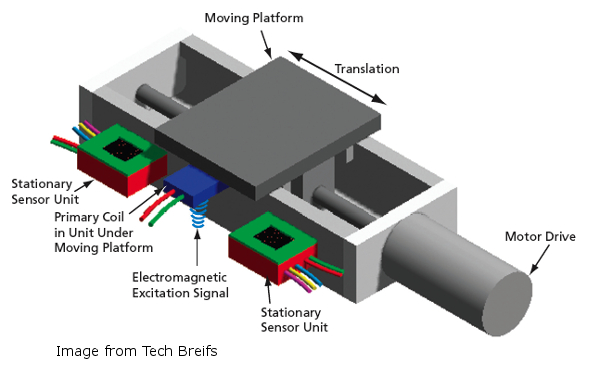

Suruga Seiki 's PG Series linear motorized translation stages are a great fit for applications which require a good accuracy combined with a relatively large travel range. These motorized translation stages are particularly popular in laser optics, spectroscopy, microscopy, and metrology applications. A motorized linear translation stage is used to precisely position an object along a single axis. Motorized linear stages include a moving platform and stationary base joined by a bearing system.

A motorized linear stage is essential for a wide range of applications, and provides programmable control of position in one or more axes.

There are multiple technologies to choose from when selecting a motorized linear stage. The simplest is based on a stepping linear motor, with its rotary motion converted to linear motion via a pulley and belt, or a lead screw.

Fully integrated stepping linear motor/lead screw assemblies have recently become widely available. They avoid the need for a rotary coupling and a lead screw bearing, and provide a compact, cost effective solution for many motorized linear stage requirements.

A higher performance and higher cost solution replaces the stepping linear motor with a brushless rotary servo motor. While these can achieve higher speed and precision, they require a rotary encoder and are not yet available as integrated motor/lead screw assemblies.

Figure 1: A Dover KV™ micro linear stage is a lead-screw-driven stepper motor stage.

Getting the Best Performance from Your Motorized Linear Stage

The highest performance approach to designing a motorized linear stage is to make the switch from rotary stepper driven motors to direct drive linear motors. In this approach, the motor delivers force directly to the payload and a servo loop is closed based on feedback from a linear encoder.

Direct drive solutions for motorized linear stage requirements have traditionally been an expensive option. Direct drive technology has evolved and is now available at a more modest price point due to recent advances in magnetic material performance and cost, as well as cost reductions in linear encoders.

The value increases when the full life cycle costs of the motorized linear stage are considered. Motorized linear stages utilizing direct drive also provide a dramatic increase in system throughput through a reduction in move and settle time.

Figure 2: The Dover AirGlide™ stage features a direct drive linear motor and ultra-precision air bearings

Linear Positioning System

Finding the Right Motorized Linear Stage for Your Application

We offer a variety of products featuring the most precise and cost-effective direct drive linear motors available today. Our products with motorized linear stages offer low profiles, long travel, miniature sizing, and ultra-precision air bearings. And each of our stages are configurable to best fit your unique application. For the last 50 years we have been collaborating with our clients to build them the right motions solutions. Contact us today to learn how we can work together on your next motorized linear stage.

Linear Stage Motorized Motor

In Need of a Motion Solution?

Browse our Linear Motor Stages here